The Reinvention of Khadi

THE SLENDER HENNAED FINGERS OF A woman in Karnataka's Bandanvalu village disentangle coarse white cotton threads with one hand as she runs the charkha with the other. Gandhi's iconic spinning wheel has made for many a postcard, but this is not a set for a photograph. This is a Khadi product in the making. Around 2,000 kilometres away, fabric woven from this yarn will be dyed and tailored to perfection for someone. It could be for anyone, from a postman to the Prime Minister.

Less than a week before Prime Minister Narendra Modi's birthday on September 17th, the Noida-based Hidesign Fashion's tailoring house was working round-the-clock to stitch 100 Modi jackets and 200 Modi kurtas of handspun fabric. The Modi jackets are available in four styles: buttoned and double-breasted bandhgalas and V-necks. The bandhgala or mandarin-collared version differs slightly from the Nehru jacket, which is fully buttoned at the neck and has smaller armholes. The Modi kurta is buttoned-up and half-sleeved, a signature style he established whilst he was Chief Minister of Gujarat. Pre-shrunk cloth of 15 different colours has been used for this collection, with both cotton and silk as yarn from various parts of India, and it boasts of prints as well as dyed materials. Given the retail success it was proving, the order quantity had to be increased to 5,000 jackets and 1,000 kurtas over the subsequent fortnight—to be stacked on the shelves of the Capital's flagship Khadi outlet alongside Western-wear by designer labels like Ritu Beri.

Khadi has been woven with nationalism ever since Mahatma Gandhi made it a symbol of self-reliance in the fight against British rule, but as a brand imbued with the spirit of a nation, it has transformed itself over seven decades from a humble fabric to a fashion statement, from clothing of the poor to attire for the man or woman about town.

Independent India's leaders have paid tribute to Khadi through their own sartorial styles down the decades. The Nehru jacket, named after the country's first Prime Minister Jawaharal Nehru, has gained in popularity with every generation, and is available to this day in Khadi wool, cotton or silk. His daughter and former Prime Minister Indira Gandhi took to saris made of the material, and her wardrobe attained such a legendary status that it remains a parlour game in Delhi to spot one worn by her granddaughter Priyanka Gandhi or grandson Varun Gandhi's wife Yamini at weddings and other gatherings. Indira Gandhi, whose taste in textiles was said to bear the influence of Kamla Devi Chattopadhyaya and Pupul Jayakar (her cultural advisor), was a keen shopper of saris and would visit various exhibitions to select them. Her son Rajiv Gandhi, who succeeded her as prime minister after her 1984 assassination, would often be seen in a woollen shawl of Khadi, a shoulder drape that's still sold as the Rajiv shawl at Khadi outlets. One story has it that Morarji Desai, who was prime minister in the late 70s, gave autographs only to people dressed in Khadi. While white and lighter shades had been the preference, the former diplomat and United Front Prime Minister IK Gujral marked a break from that tradition in the late 90s by adopting dark bandhgalas.

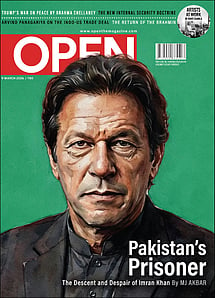

Imran Khan: Pakistan’s Prisoner

27 Feb 2026 - Vol 04 | Issue 60

The descent and despair of Imran Khan

Two decades later, the Khadi on display in the Capital has gone kaleidoscopic, with an entire range of hues appealing to a market keen to exercise a new freedom of choice. It is in keeping with this new spirit that Modi has adopted and held Khadi aloft as symbol not just of fashion but also of transformation. Images of the prime minister are to be seen with him at a charkha in white kurta-pyjama and a beige jacket. At a Mann ki Baat broadcast on radio last June, he appealed to people to use objects of Khadi as gifts—say, like a handkerchief. It is not just a domestic campaign for Modi. What was once an emblem of Indian defiance of textile imports, in his view, could now be an export winner in the era of globalisation along the lines of yoga.

To achieve that aim, the Delhi-based Khadi and Village Industries Commission (KVIC), a statutory body formed under a 1956 Act of Parliament, has drawn up a plan that draws on the fabric's inherent appeal and the talent of 26 inhouse designers. "We have changed the tailoring. Earlier, there was no consistency in design, the colour bled, and there was shrinkage. We have selected the best in tailoring being used by brands like Zara, H&M, Calvin Klein and GAP," says VK Saxena, chairman of KVIC. Since the fibre has no carbon- footprint whatsoever, he says, its eco-friendly attributes make it ideal as ethical-wear. This is something the youth have to be made aware of.

There are other initiatives as well. KVIC has approached various Public Sector Undertakings with a proposal of using Khadi gift coupons. "Generally, they (PSUs) give their bonuses as gift coupons," says Saxena, "ONGC was planning to give Rs 10,000 as a bonus to its employees. We offered a 30 per cent discount and gave Rs 13,000 gift vouchers. Sales of Khadi products empowers Indian artisans." The ONGC offer resulted in business worth Rs 42 crore. A similar agreement has been signed with IOC, from which KVIC expects to generate a similar sum. Earlier, it had a similar pact with NTPC.

Another plan involved getting some 80,000 postmen and women to switch to Khadi uniforms. However, according to sources, since money was given to them to get these clothes stitched, only 3,000-odd orders were placed. Other public workers are being roped in. Around 20,000 employees of Patna Municipal Corp, for example, are soon to go Khadi. "I had requested that if swachhata employees wear Khadi, it would be a homage to Gandhi's message of Khadi and cleanliness," says Saxena.

The Commission's efforts have boosted Khadi sales, claimed to have grown by 31 per cent from 2015 to 2018, significantly faster than the 6.25 per cent recorded from 2004 to 2014. As many as 728 Khadi outlets—no longer called 'Bhandars'— have been refurbished in recent years, franchised shops opened and shopping hours extended, even as other measures were adopted along the production chain to get more fabric rolled out. Wages for Khadi artisans have been raised from Rs 4 per hank (in the textile industry, a hank is a coiled or wrapped unit of yarn) in 2015 to Rs 7.50, for example, and 30,000 charkhas distributed. With an eye now on the international market, KVIC plans to hold exhibitions in 15 countries to coincide with Mahatma Gandhi's 150th birth anniversary celebrations that begin on October 2nd.

OR GANDHI, THE CHARKHA SPUN MORE THAN yarn. It was a non-violent weapon of resistance, a way for Indians to free themselves of the British mill trap, a means of mass dignity and a common thread of the poor and the rich. All cloth before the mid-19th century was handspun and handwoven, with Indian textiles a marvel of the world. According to textile scholar Rta Kapur Chishti, India's decline as a production centre was marked by British imports of Lancashire yarn followed by fabrics churned out by machines. "The handspun was hit first and then plain fabrics, natural or dyed," says Chishti.

Determined to secure local livelihoods and prevent an abject dependence on imports, Gandhi roused thousands of Indians to adopt manual charkhas and spin yarn for handwoven fabrics, encouraging them to make a discipline of it that spoke to their faith in themselves. However, mills for mass production could not be resisted and they were inevitably set up in India as well, which meant that handwoven clothes would never have too large a share of the market. Imported chiffons were popular among royal families, for example, a clientele that mills in Mysore began catering to. Personal self-sufficiency of clothing was to prove impractical but would acquire symbolic value for its spirit of independence.

Other spinning contraptions have come along too. An alternative to the Gandhi charkha was a two-spindle wheel developed by a gentleman named Ekambernath to increase productivity. Today, multiple-spindle variants abound, some of them using an electric motor to drive them. "The fabric should be marked either 'mechanised' or 'handspun on traditional charkha'," says Chishti, emphasising that the consumer should be aware of the distinction. By the KVIC definition, Khadi is any cloth that is woven on a handloom in India from cotton, silk or woollen yarn handspun in the country (mixtures of such yarns are included too).

The Amber charkha, which has been certified by KVIC as a spinner of genuine Khadi yarn, is widely used. Of the estimated 925,000 wheels in the country, 257,000 are of this sort. Of the rest, some 667,000 are original Gandhi charkhas and 2,400 are solar powered.

Manual operations also mean that the country's overall Khadi capacity is limited by the hands available to spin yarn and weave fabric. Spinning is an extremely slow process and that is the biggest constraint on expansion, says Vijaya Switha of the Hyderabad-based Chitrikha Foundation, which aims to transform weavers into entrepreneurs. It takes a spinner to make as much yarn in a year as it takes a weaver to weave in a month. "Real handspun Gandhi charkha Khadi costs around Rs 1,500 a metre," she says, "so a six-yard sari can go up to Rs 7,000-9,000." Such high price tags limit the market for Khadi products, which in turn deters private investment in the sector for anything other than cottage-scale operations for the low-volume fashion industry. Also, talent is in short supply. On the classic Gandhi charkha, the fineness of the output depends on the spinner's skills. Once spun, however, Switha says it is difficult to make out the difference between a product from a Gandhi charkha and that from the Amber variant.

In Andhra Pradesh's Ponduru, famous for its Khadi, women who use the Gandhi charkha get Rs 150-200 per day, while those using the Amber muslin version earn Rs 200-250. Weavers earn Rs 300-350 a day. From 1,500 traditional spinners—mostly women—ten years ago, the number has fallen to 1,200, says J Shankar Rao, who works with the Andhra Fine Khadi Karmikabhivrudhi Sangham. The spinners of Ponduru use short-staple cotton grown in the region for single spindle operations, and this raw material must go through at least five processes—including its 'ginning' with fish jawbone—before it is spun. "Every woman working on the Gandhi charkha feels it is an honour," says Rao, whose ringtone is set to Raghupati Raghav Raja Ram, one of Gandhi's favourite devotional songs.

For all the changes since Gandhi's day, there are still many Indians who live in Khadi for the sentiment of it. Take Musadilal Gupta, 75, a retired government employee and resident of Alwar, Rajasthan, who wears clothes of fabric made only of what he himself has spun on a his peti charkha, a spinning wheel in a box. "Whenever I get time, I spin," says Gupta, whose interest in it was aroused when he read books on Gandhi in school. He spins for himself and his sisters, living out Gandhi's very own ideal.

For KVIC, protecting Khadi as a brand is an important objective. It even filed a case in June against Fabindia at the Bombay High Court for selling garments as Khadi, contending that it had not granted the retailer the right to sell garments under the brand (Raymond and Arvind Mills are among those that may use the trademark); Fabindia has undertaken not to persist with that name. For the overseas thrust, Indian missions have been asked to help. Earlier this year, the fashion designer, Gavin Rajah, choreographed a 20-minute textile event aimed at popularising Khadi at the Sandton Convention Centre in Johannesburg. A tribute to Gandhi and Nelson Mandela, the event was held to commemorate 125 years of the Pietermaritzburg incident where Gandhi was thrown out of a train by White supremacists.

There have been many Central efforts to revive the Khadi sector. In the mid-1990s during PV Narasimha Rao's tenure as prime minister, a scheme was implemented to fund the Khadi sector. At the turn of the century under AB Vajpayee as prime minister, an Arthur Andersen study had recommended— among other things—that KVIC structure itself into separate business units to meet the separate needs of the Khadi and village industries.

The real renaissance appears to have come only now. "All governments have tried to encourage Khadi in their own way," says Satya Narayana, deputy CEO, north zone, KVIC, "But Modi is the first Prime Minister to mention it from the ramparts of Red Fort on Independence Day."

It was the force of conviction that set the wheel in motion. It is renewed dedication to Gandhi's ideals that will keep it that way.