Viral Biscuit

BACK in May, after she had tired from waiting for the lockdown to be lifted, Asha Gaikwad put her three-year-old child on her husband's shoulder, and holding her five-year-old by one hand, set out for her home some 300 km away. Gaikwad, who worked as a domestic help in some homes in Navi Mumbai, was going back to her village close to Kolhapur in Maharashtra, a journey that would take several days on foot.

But before she set out, she began to pack for the journey. She carried some chapatis that would not last beyond a day, some fruits, such as bananas, some bottles of water, and then, just a few days before her journey, like many others in her position, she began to scour the small neighbourhood shops and reach out to NGO workers for packets of one particular biscuit brand—Parle-G.

"It [Parle-G] was the best thing. Because unlike [cooked] food, it was never going to become stale, it is easy to carry, and my children love it. Every time they became hungry or irritable, we would eat the biscuit," she recalls.

Gaikwad and her family did not have to walk all the way home. They walked for some time, hitched a few rides on the back of trucks carrying essential supplies, and rested at a shelter home mid-way for a few days, before finally finding a bus that would take them to their village.

But the Gaikwads were not the only ones looking for Parle-G before they embarked on their journey. The migrant labourers carrying Parle-G biscuits who left the cities for their ancestral villages comprisedonly one section of individuals. There were others too. When India imposed arguably the harshest lockdown in the world, and food and other necessities suddenly became scarce, people across economic and social strata began to raid their neighbourhood shops for the biscuit in the familiar yellow packaging.

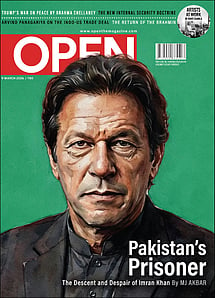

Imran Khan: Pakistan’s Prisoner

27 Feb 2026 - Vol 04 | Issue 60

The descent and despair of Imran Khan

The lockdown was a catastrophe for almost every industry. And most businesses are still reeling from the economic after-effects of that period. But for a tiny fraction, particularly those in the packaged food industry, the lockdown created an immense opportunity. The demand for all types of food products, from instant noodles, breakfast cereals, wafers, to arguably the most in-demand commodity in that period, biscuits, skyrocketed. And within the biscuit category, none was more in demand than the humble Parle-G.

"The scale [of demand] was unprecedented," says Mayank Shah, the senior category head at Parle Products, the company that makes Parle-G. "Whatever we made [in that period] and brought to the shop aisle, it vanished almost instantly."

During the lockdown, the demand for the biscuit went up by nearly 80 per cent. Parle Products, which is a privately held company, did not disclose how much exactly this demand materialised into business for the company. But Shah reveals that in this period, the market share of the company expanded by about 5 per cent, about 90 per cent of which was entirely on the back of the sales of Parle-G biscuits. This is a significant market share increase because the biscuit industry is highly competitive, and all biscuit-makers were seeing significant growth in this period, with Parle Products' main rival Britannia having long gone past the old company in market size with its premium portfolio of cookies and creamy biscuits.

The increase in demand for the biscuit began even before the lockdown. About two weeks before March 23rd, Shah says, the company had begun to notice that stores were reporting low stocks. This was caused by individuals learning about the rise in cases abroad beginning to hoard on packaged food. By the evening of March 23rd, after the announcement, everything in shops had vanished. From the next day, the company was inundated with calls from the Centre, various state and local administrations, apart from NGOs and distributors. "They wanted to know if we had enough supplies to help people tide over this period," Shah says.

Parle-G isn't like another normal biscuit. For a long time, this was the only biscuit brand most Indians were familiar with. Established by Mohanlal Dayal Chauhan in 1929, and named after the Mumbai suburb, Vile Parle, where the first factory was set up, the brand took biscuits, then consumed mostly by British officers and businessmen and the Indian elite, and made it a product for the masses. Parle-G was first called Parle Gluco. The name-change occurred in the 1980s, when the company tried to distinguish itself from the many rivals who had begun to imitate the company and use the word 'glucose' in their packaging. Over the years, Parle-G became synonymous with biscuits. It crossed economic divides. The rich dunked their Parle-G in tea or milk, as Shah likes to say, while the poor did so with a glass of water. For many Indians, it also became their first taste of processed food, consumed when mashed with milk. Whenever mothers were too caught-up with work or were under the weather, the children opened their lunchboxes in school later that day to find a packet of the biscuit. "It is a tradition. My mother used to give it to me as a kid. And I do so with mine," Shah says.

In the pandemic, people rushed to buy this biscuit, analysts point out, because people trusted the brand, and in the case of migrant labourers, it was inexpensive, easy to carry, and a quick source of nourishment. During disasters, Parle-G is often among the first products to be distributed by NGOs and government bodies for relief work. Even during this pandemic, when NGOs distributed cooked meals, they often found many of them spoiling by the evening.

Over the years, while many affluent Indians have moved on to other, more expensive, varieties of biscuits, the biscuit still continues to be consumed in huge numbers. The company produces around 400 million Parle-G biscuits every single day, probably the highest-selling biscuit in volume anywhere in the world.

When the lockdown struck, it created a huge opportunity for business. But it was going to be far from smooth sailing.

LIKE SEVERAL other large companies, Parle Products had begun to anticipate something was afoot nearly two weeks before the lockdown was announced. Looking at the news of rising cases the world over, its management began to work towards preparing contingency plans. "Back then we thought there could be curfews imposed over a small area by the local administration. We were worried there might be a disruption in supply in case curfews came up in places where our factories are located. So we increased production and began to move the finished products to our depots. We thought if there was going to be a curfew, we should have our stocks outside it."

When the lockdown was announced, Parle Products like everyone else, was stumped. For only the second time in its history, its factories closed. (The first being when India was partitioned.)

Parle Products makes 400 million Parle-G biscuits in a normal day. It is a mammoth exercise that involves around 1 lakh individuals working in the 10 large factories the company owns, another 120 contracted manufacturing units elsewhere, and the various depots and ancillary services connected with the production and distribution of biscuits.

Just a single day's work stoppage could potentially mean many individuals across the country going hungry.

Parle Products' management, through industry bodies, began to approach the Government to restart production. For the first few days, there remained an ambiguity as to who would be allowed to reopen. While some states and local administrations considered biscuits essential items, others did not. Two days after the company shut down, once clarifications were obtained, the factories began to thrum with work again.

But navigating the lockdown and its myriad rules, while demand skyrocketed, was going to be a complex affair. Only a few of the total 130 factories were able to restart, that too till their raw materials lasted. Later, while the transportation of food ingredients that went into the making of Parle-G became smooth, the company's officials began to face difficulties in getting packaging material transported. "[Transporting] the packaging material was sorted after a while. After all, the police on the street could see it is Parle-G's wrapper. But what about the film that the printer uses [in the packaging material]? Who will be able to judge whether that film is being used in making Parle-G's wrapping material or something inessential?" Shah recalls.

All these seemingly minuscule challenges were make-or-break situations given the large volumes they needed to churn out.

And then the issue of the migration of labourers surfaced. Parle Products employs a vast number of labourers across its factories. Even while the various state governments were slowly increasing the permissible limit of employees allowed to work at a site, the company was struggling to find workers.

The company had to reorient processes. They dumped those biscuits that took up too much manpower, or reduced the production of those that used excessive and time-consuming packaging, such as the large Parle-G pack that costs Rs 100, with multiple smaller packs inside. Employees began to live on the factory premises, working in 15-day shifts before the next batch relieved them. The focus from hereon was going to be the production of Parle-G biscuits.

Despite the much reduced workforce and the various limitations, in about a week's time, production had increased to nearly 90 per cent of past capacity. In another three works, they were up at 100 per cent.

"You have to understand the huge volumes we deal in. Imagine 400 million biscuits in a single day. Internally, we were all geared up. We realised that we were partly responsible for the food security of the country. We had a moral responsibility to ensure no one went hungry," says Shah.

THE BISCUIT industry has been changing rapidly in the last two decades. Parle-G may be the most widely consumed biscuit in the country, but it is no longer the most valuable.

Parle-G sells at about Rs 77 per kg. It falls in what is called the affordable or value category. At the start of this century, this category may have comprised between 60 to 70 per cent of the market share. But that is not the case anymore. It accounts for 50 per cent of all sales, but just one-third of overall revenue. As the country has become wealthier and more aspirational, its taste in biscuits has also gravitated towards premium biscuits. And this bridge between value and premium markets, in a biscuit industry pegged at Rs 36,000 to Rs 37,000 crore in the last fiscal year, is expanding rapidly.

This value segment of glucose biscuits first ran out of energy, according to a Forbes article, in 2012. The momentum has only gathered pace ever since. 'In March-ended FY2020, the glucose market size was at Rs 5,444 crore, a muted growth over the last year, when it was Rs 5,442 crore. Parle had a staggering 83 per cent value market share. Rival Britannia had a meagre 10.4 per cent…With a market size of Rs 9,429 crore in the March-ended fiscal 2019-20 (from Rs 8,600 crore a year before), Britannia had a thumping 57.3 per cent market share in premium biscuits. Parle is distant third with 9.4 per cent, and behind ITC, which garnered 17.1 per cent. In premium cookies (over Rs 5,500 crore category), Britannia lords with 67.6 per cent,' the article reads.

Abneesh Roy, executive vice president, research, at Edelweiss Securities, who tracks the market of consumer products, points out that even in the last two years, Parle Products has been rapidly losing its market share to Britannia. "Britannia is a stronger brand, and it is rapidly increasing its distribution [networks]," Roy says. He points out that Britannia is making rapid inroads even in the Hindi belt of Madhya Pradesh, Uttar Pradesh and Rajasthan, and Gujarat, where Parle Products has always held a sizeable market share.

This coincided last year with the economic slowdown in the country. At some point, the company revealed that it could be compelled to lay off about 10,000 employees of the one lakh that earn a livelihood from it.

According to analysts such as Roy, Parle Products' difficulties stem from the fact that, despite coming out with premium categories of its own, it continues to focus most heavily on a category of biscuits that is fast losing out to more attractive fare. "Parle-G may be the cheapest biscuit. But consumers don't want the cheapest biscuit anymore," he says.

That may have changed during the lockdown. Those that had appeared to have moved on from the biscuit, rediscovered it. Twitter was awash with images of people sharing photos of Parle-G with their evening tea. Publications carried recipes of sweet dishes one could make with Parle-G. Shah talks with amusement how he came across people using the biscuit to bake cakes and even sweets like ladoos.

The demand, since the lockdown, has tapered off. But it is still higher than pre-Covid-19 levels, and Shah points out that the company expects it will further rationalise as more people begin to step out and look for other products to consume.

"This whole period [of the pandemic] has given us a lot more than just business," Shah says. "The way it panned out, a huge goodwill has been generated. It has created great brand love. And that is more valuable than anything else."