Powering the War Economy

OPERATION SINDOOR, INDIA'S military response to Pakistan-sponsored terror attacks in Pahalgam on April 22 that killed 28 innocent people, mostly tourists, is many things to different people. For the majority of Indians, it marked a shift in the country's military strategy towards treating any such carnage as an act of war which will be met with a hugely disproportionate response, as evident from the four-day limited war that targeted not only locations in Pakistan and Pak-Occupied Kashmir where dreaded terror outfits such as Lashkar-e-Taiba and Harkat-ul-Mujahideen had set up bases, but also military bases of the Pakistan army, which often assumed that its nuclear deterrence would stop New Delhi from escalating the war. For many others, it was an occasion on which India showcased its military prowess for the whole world to see.

For Professor Sanjay Bakshi, the war with Pakistan was an inflexion point for India's defence manufacturing capabilities. The man known for his incisive takes on a range of subjects, this managing partner at investment advisory firm ValueQuest Capital LLP (who is also distinguished adjunct professor, Finance, at Flame University, Pune), sees Operation Sindoor as an inflexion point for local defence manufacturing "just as Y2K was for India's IT services industry, and UPI was for India's payment systems leapfrog into becoming what they have become."

It is in this context of market optimism and the government's quest to rapidly modernise the country's defence preparedness that the news about Raphe mPhibr, an Indian defence-tech and aerospace startup, raising $100 million in a funding round led by General Catalyst, assumes significance. Think Investments, Amal Parikh and other family offices also participated in the round, bringing the company's total funding to $145 million. It was great news indeed, because it marked the largest private capital raise in the country's aerospace manufacturing sector to date. Founded almost a decade ago by siblings CEO Vivek Mishra and Chairman Vikash Mishra, the Noida-based startup designs and manufactures a range of unmanned aerial vehicles (UAVs), including the mR10 drone swarm platform, the mR20 high-altitude logistics drone, Bharat (a man-portable surveillance drone), and X8 (a compact maritime patrol system).

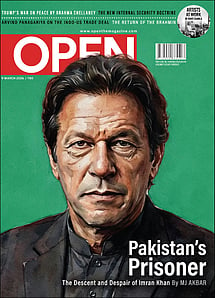

Imran Khan: Pakistan’s Prisoner

27 Feb 2026 - Vol 04 | Issue 60

The descent and despair of Imran Khan

In an exclusive interview to Open, the company says its efforts clicked because their plan from the start was to build systems for the need of the country. CEO Vivek Mishra, 35, tells Open in an interview that as soon as he and his brother returned from studies in the US in 2017 and launched the company, they started with the simple goal of building defence aerospace and deeptech for India according to the needs. "Initially, for 3-4 years, it was only about research in terms of the different needs, environment and terrains. Since we have varying terrains in India, operational needs change accordingly."

As of now, he adds, "We can do around 2,500–3,000 drones per year. But we are an aircraft manufacturing company. The idea is to build systems for the need of the country. The kind of research and manufacturing facilities that we have built, we can build any system today. We are increasing our capacity in terms of the autonomy, intelligence, size and weight of the systems. There will be exponential growth over the next decade." The company has been providing UAVs to Indian security forces since their first commercial launch.

Raphe mPhibr isn't the only company that stands to benefit from developing what are now war-tested indigenous defence systems, and they alone can't be, simply because of the reasons that Professor Bakshi has outlined in a recent podcast with Open columnist Anil Padmanabhan. Bakshi has highlighted the force multipliers for this fast-emerging trend. The first, according to him, is the role of incentives from the financial markets, the venture capital and private equity industry, and the government, in the rapid development of India's defence capabilities. The second is, of course, the role of Operation Sindoor in putting the spotlight on India's defence equipment and capabilities, which the world had an opportunity to take note of. Most importantly, he sees this welcoming trend spur growth in myriad sectors because, he believes, defence startups have set an example for how India can use its frugal innovation techniques in so many other industries as well to acquire a competitive advantage in the defence exports business.

A word on the government's push in the segment. Besides multiple other schemes, the Centre is also financing such startups. For instance, the iDEX scheme, funded and managed by the Defence Innovation Organisation (DIO), which falls under the Department of Defence Production, Ministry of Defence, provides grants up to ₹1.5 crore (up to ₹10 crore in case of iDEX Prime) to startups/MSMEs to fund the projects in many technological areas under "Defence India Start-up Challenges (DISC) and Open Challenge through the Support for Prototype and Research Kickstart (SPARK Framework)".

AS LUCK WOULD have it, stocks of such defence companies that are listed have seen a marked growth thanks to Operation Sindoor. ideaForge Technology, which provided surveillance drones to the Army, saw its share prices soar massively. Paras Defence & Space Technologies, which supplied both surveillance and kamikaze drones, also saw a jump in its share prices. Others that performed well on the stock markets include Solar Industries India Ltd (which developed the Nagastra 1R loitering munition, a night-capable drone tested in key regions); Adani Enterprises (whose subsidiary Adani Defence & Aerospace deployed its SkyStriker kamikaze drones and anti-drone defences in Operation Sindoor); and so on. Other companies that attracted global attention lately are Tata Advanced Systems, Asteria, Raphe, Adani Alpha Design, all of which offer a full suite of weaponry, from loitering munitions and surveillance UAVs to drone-swarm and logistics support systems.

Sales and orders are going up, too, at a fast clip. Open had reported earlier that as of now, more than 100 Indian firms are exporting defence products from India, according to official statistics. Major buyers include Italy, the Maldives, Russia, Sri Lanka, the United Arab Emirates (UAE), the Philippines, Saudi Arabia, Poland, Egypt, Israel, Spain, Chile, and others. As they say, the proof of the pudding lies in the eating: defence exports have seen a significant growth, rising from ₹686 crore in 2013–14 to ₹21,083 crore in 2023–24. And the Centre expects defence exports to reach ₹50,000 crore and annual defence production to hit ₹3 lakh crore by the 2028–29 financial year. Defence production already crossed the ₹1 lakh crore mark in 2023–24.

In an analysis, Open had reviewed the performance of Indian companies on the sales front. As of now, India's defence-industrial base includes more than 16 defence public sector undertakings (DPSUs), over 430 licensed private companies, and around 16,000 micro, small and medium enterprises (MSMEs).

The private sector, quite interestingly, now contributes 21 per cent to overall defence production. Among PSUs, major players in the Indian defence sector include: Hindustan Aeronautics Ltd, Bharat Electronics Ltd, BEL Optronic Devices Ltd, Bharat Dynamics Ltd, BEML Ltd, Mishra Dhatu Nigam Ltd, Mazagon Dock Shipbuilders Ltd, Garden Reach Shipbuilders & Engineers Ltd, Goa Shipyard Ltd, Hindustan Shipyard Ltd, Gliders India Ltd, Troop Comforts Ltd, Armoured Vehicles Nigam Ltd, Munitions India Ltd, Yantra India Ltd, Cochin Shipyard, India Optel Ltd. Private ones include the Adani Group, Reliance Ltd, Bharat Forge, Mahindra, Tata Group, L&T India, and Punj Lloyd, among others.

In fact, India's defence exports now span a broad spectrum, ranging from arms, ammunition, and fuses to complete weapon systems. Indian firms are exporting advanced platforms such as the BrahMos supersonic cruise missile, artillery guns, Dornier-228 aircraft, radars, Akash air defence missiles, Pinaka rocket systems, and various armoured vehicles.

It comes as no surprise then that the Nifty Defence Index significantly outperformed benchmarks, driven by increased investor confidence and anticipated procurement cycles, as reports continue to confirm. Again, defence capital expenditure and procurement timelines have accelerated.

None of this was attained by a sudden flight. In an interview with Open earlier, Retired Major General AK Channan, who was closely associated with the Make-in-India defence initiative since 2014, had pointed out that the changes that happened over the past decade were when "the idea of procurement changed to acquisition." He was referring to the Defence Procurement Procedure (DPP) of 2002 (which envisaged reduced delays of procurement in line with the needs of the Armed Forces) that gave way to the Defence Acquisition Procedure (DAP) of 2020 (which was meant to simplify targeted acquisitions) and the reliance on Make-in-India followed by Aatmanirbhar (self-reliant) initiatives by banning imports of certain defence components to catalyse Indian defence production and technology. Earlier, the Armed Forces acquired anything available for purchase as it diversified its portfolio by approaching newer countries to reduce dependence on any one country or a few of them. Channan had noted in an interview to Open that a paradigm shift took place after DAP was implemented and later when the government started giving incentives to local players to design and manufacture defence products. By restricting imports, companies felt the need to forge ahead with their plans.

A reflection of this change is obvious in this assertion by Vivek Mishra, "We don't make a product and push it to the customer. The user tells us first what they need. They tell us what operational capability and quality assurances are required. We then use those inputs to build a system. So, it is just not customised for the clients but built from scratch according to their requirements. That is the true sense of Make-in-India which we are trying to follow. As far as the applications [for Operation Sindoor] go, they are determined by the user [Armed Forces]. For example, we designed and developed logistics UAVs for high altitudes, which was again the world's first. They have been deployed by the Armed Forces and are flying in large numbers over the last two years. As of now, all our customers have been in the Armed Forces. But we would be happy to take on other challenges too."

Raphe mPhibr is a peculiar name where the first part is pronounced ray-phee (denoting the combination of two tissues in the body). In mPhibr, the 'm' stands for myelin, the protective sheath on the neurons which helps in the communication and control of our body parts. So, "raphe and myelin together talk about the ethos and the kind of things we are working on, which is about the building blocks of any system—materials, composites, electronics, software and controls. And raphe and myelin are joined by a fibre. We couldn't get the 'fibre' name to register and so settled for 'phibr'. We took 20 days to come up with the name," Mishra elaborates.

With more companies across the private and public divide brandishing their feats in Operation Sindoor, the four-day offensive from May 7 against Pakistan, and a favourable market ecosystem emerging to promote manufacturers, it looks like India's indigenous defence segment is pushing the boundaries of innovation and ambition.