‘We build from scratch according to our clients’ requirements and that is the true sense of Make-in-India which we are trying to follow’

The success of Indian drones in Operation Sindoor did not go unnoticed as the Noida-based unmanned aerial vehicle (UAV) maker Raphe mPhibr's flowing order book would attest. The company recently made headlines by bagging a record $100 million funding in the aerospace industry from General Catalyst, with participation from Think Investments and other backers. In a candid chat with Moinak Mitra, Raphe mPhibr Cofounder and CEO Vivek Mishra, 35, lays bare the DNA of the company and provides cues for the road ahead. Excerpts:

What does the name of the company mean?

It is pronounced ray-phee (like referee). Usually a combination of two tissues in the body is called raphe. In mPhibr, the 'm' stands for myelin, the protective sheath on the neurons which helps in the communication and control of our body parts. So, raphe and myelin together talks about the ethos and the kind of things we are working on, which is about the building blocks of any system—materials, composites, electronics, software and controls. And raphe and myelin are joined by a fibre. We couldn't get the 'fibre' name to register and so settled for 'phibr'. We took 20 days to come up with the name.

Which year did you set out and how did the company evolve?

The idea for building UAVs was conceptualised in 2016 when me and my brother (Vikash Mishra) were studying in the US. We registered the company in 2017 when we returned to India. We started with the simple goal of building defence aerospace and deeptech for India according to the needs. Initially, for 3-4 years, it was only about research in terms of the different needs, environments and terrains. Since we have varying terrains in India, operational needs change accordingly. We studied that and did research on how to build an aircraft, build the scientific recipe behind it, simulation and analysis techniques. In late 2019, we started delivering products. From Day One, the idea was to have research capability along with manufacturing capability because working in the US we were spoilt with good research infrastructure and a strong ecosystem. The design must be as good as the manufacturing capabilities. If you are restricted by manufacturing capabilities, then you can be the best designer, mathematician or scientist, but all that will be of no use. That is why we were always focused on building manufacturing facilities here. Right now, we have more than 600 people here spread over both research and manufacturing—on 6.5 lakh square feet of land—where we do state-of-the-art manufacturing like additive manufacturing, which is 3D printing around metals and thermoplastics with around 30 different materials, as well as subtractive manufacturing. We have quality assurances for all these processes. Then we have a military-grade electronics manufacturing and wire harness manufacturing.

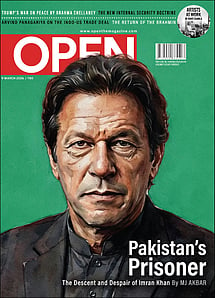

Imran Khan: Pakistan’s Prisoner

27 Feb 2026 - Vol 04 | Issue 60

The descent and despair of Imran Khan

You seem to have a robust product pipeline?

We were very clear from the beginning that for building systems, you need subsystems. The quality of the subsystems builds up to the quality of the system. We focused on research and manufacturing of subsystems and the systems we produce are in the aerial vehicle domain, almost all of which is unmanned aerial vehicle. But again, the capabilities that we have built towards this can be utilised for manufacturing any reliable military-grade or aerospace system. So, the main vision has always been to build capability so that research and manufacturing can be done under one roof.

What does your tagline 'Pratyansh Kim Pramanam' mean?

It means, 'something that is in front of you doesn't need proof'. We produce high-quality equipment and subsystems. If you see our facility, we don't have to talk about it. So, the proof is indeed in front of you.

How do you assemble such a vast number of people, including several expats, under one roof?

Me and my brother are technical people. We know how to handle technical things, how to learn new machines, how to not just go into operations but even commissioning. So, we learnt every machine by ourselves and then we imparted that knowledge to people who had joined us. We still do that. It is an intense programme for whoever joins us. We teach them physics, mathematics, engineering, and after a year-and-a-half, and in some case even six months, they are job-ready. We do not expect our new joinees to deliver from the word go because the kind of things we do are niche. Nowadays, sometimes we get experts, and in the areas where we don't have experts, we learn ourselves and hand over the baton. But we have few experts and largely for people who join us, the intensive training is a must.

What are some of the challenges you've faced?

If you talk about metals, it is a different challenge. For composites, it is a different challenge. Me and my brother have complementary skills, although they are different. He handles mechanical and aerospace. I handle electronics, robotics and the controls side of things. But the basic mantra is to do the hard learnings diligently and then train others. Definitely, additive manufacturing has been helpful in producing complex parts but again when people talk about additive manufacturing, a lot of it goes into recreating what exists. So, when we did our designer internal combustion engine (ICE), which was India's first, we actually redesigned the whole thing. We made it more efficient, lighter and smaller by using the concepts of science.

Why get stuck in the ICE age at the time of electric vehicles (EVs)?

If we talk about energy density, no battery can beat fossil fuels. If the UAV weighs 10kg, on battery it will fly for 60 minutes. But if the drone has an ICE, it will fly for 2-3 hours. The engines that have been developed around the world for UAVs have been copied from the automotive industry. The needs of those drones are different. They don't need to be very light. It is different for us. When we were scouting for engines, we were not getting the right fit—they were either too heavy or too expensive or would not meet performance standards. So, we had to design one (using petrol), which was India's first UAV engine designed in-house. Similarly, we designed India's first military-grade auto pilot.

Are the body parts made of composites?

Yes, the biggest facility we have is the carbon fibre composite manufacturing facility. Most of the parts are made of carbon fibre composites. We do everything in-house because manufacturing complex drones like we do is not an easy task. We do research in manufacturing as well so that we can pull off what we dream of in the design.

How were your drones chosen for Operation Sindoor?

Since our first commercial batch, we have been providing UAVs to Indian security forces. We don't make a product and push it to the customer. The user tells us first what they need. They tell us what operational capability and quality assurances are required. We then use those inputs to build a system. So, it is just not customised for the clients but built from scratch according to their requirements. That is the true sense of Make-in-India which we are trying to follow. As far as the applications (for Operation Sindoor) go, they are determined by the user (armed forces). For example, we designed and developed logistics UAVs for high altitudes, which was again the world's first. They have been deployed by the armed forces and are flying in large numbers over the last two years. As of now, all our customers have been in the armed forces. But we would be happy to take on other challenges too.

Was the success in Operation Sindoor the real reason behind the record fund infusion of $100 million (Rs 860 crore) by General Catalyst?

No, it was planned that way. Raising $100 million from General Catalyst doesn't happen in a day. Altogether, we have an investment of $145 million into the company so far.

And what is the capacity of UAVs right now?

We can do around 2,500-3,000 drones per year. But we are an aircraft manufacturing company. The idea is to build systems for the need of the country. The kind of research and manufacturing facilities that we have built, we can build any system today. We are increasing our capacity in terms of the autonomy, intelligence, size and weight of the systems. There will be exponential growth over the next decade.