Make in India: The Sales Pitch

At an early morning session, in a hall overcrowded with Japanese and Indian businessmen and government representatives, Amitabh Kant, secretary of the Department of Industrial Policy and Promotion and one of the chief drivers behind the Centre's 'Make In India' campaign, sits brooding on the dais. One after another Japanese businessman take to the podium, humbly smiling and bowing before and after every speech, offering platitudes about the rapid growth of the Indian economy and the opportunities it offers.

When Kant's turn comes, having already zipped in and out of several sessions simultaneously going on during 'Make In India Week', he is forthright, even brusque. "I admire the Japanese," he says, "We all do. For the way you have built your post-War economy. And our two countries have always done business together. But I have to say this," at which point he looks at the Japanese delegates sharing the dais with him, "companies like those from Korea have taken your place here. You make Metro lines with us. But the Metro coaches are all made by somebody else. You should… no, you must come and manufacture here. You must penetrate foreign markets from Indian land. Otherwise Japan's growth story is over. Remember, nobody can grow forever. Your country is too advanced. Nobody…" he raises his hands to find an approximate height in the air, "can grow beyond six feet and a half." The Japanese dignitaries who have so far been nodding at each other in agreement, now look quietly at each other. "For your own sake, you must shift your manufacturing to India." And with that, Kant is gone, perhaps to another session of the grand event to offer a similar homily to another set of visiting businessmen, leaving in his wake delegates to express their opinion on India's growth story.

This is how the 'Make In India Week' campaign goes: a muscle- flexing show of strength, persuasion and extreme confidence, often bordering on the verge of being cocky.

Over the next few days, the Centre and the Maharashtra government extol the event's success by citing the commitment of large investments it has been able to secure. "India is an oasis of growth in a barren economic terrain," claims Kant, "Everybody wants to make and sell here."

But how successful has the campaign, now more than a year old, really been? Are big foreign companies looking to set up manufacturing bases here? And what about the infamous difficulty of doing business here, the bureaucratic red tape, the poor infrastructure and power supply? Is India really going to become the next China?

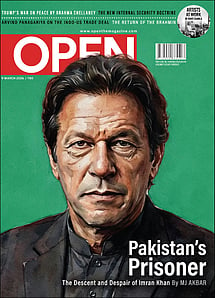

Imran Khan: Pakistan’s Prisoner

27 Feb 2026 - Vol 04 | Issue 60

The descent and despair of Imran Khan

Since the sale of its first smartphone in 2011, the Chinese handset maker Xiaomi has done incredibly well. Offering fully-loaded mobile devices for just a fraction of the cost other brands charge, the company has operated on razor-thin profit margins to become China's No 1 smartphone maker and the world's third largest after Samsung and Apple. For the first few years of its existence, 'the Apple of China', as it is often referred to, grew exponentially selling high-performance gizmos at lower prices than its rivals. But its mega success was mostly a far eastern phenomenon, and by 2014, this young company wanted to enter the Indian market.

It is interesting to note another Chinese cellphone maker's India story here. Huawei Technologies set up an R&D facility, its first overseas venture, in Bengaluru way back in 1999. But despite several proposals over the years to set up a manufacturing plant in India and to invest more money in its R&D facility, as various media reports have indicated, the Indian Government refused to grant the requisite permissions. What were the chances that this new company would be able to crack the Indian bureaucracy?

Xiaomi didn't just enter the market and start performing well, selling three million phones in its first year, and one million phones between just July and September 2015, it set up a factory about 55 km north of Chennai, in Andhra Pradesh's Sri City business township.

"Yes, we had heard about that," says Manu Jain, the India head of Xiaomi, referring to the difficulty of setting up business in India and the suspicion with which Chinese companies are viewed. "But I don't get it. Our experience with the Government has only been really good. Everything was cleared almost instantaneously."

Talks about opening such a facility began around February 2015, according to Jain. And by August, just six months later, the Redmi 2 Prime, the first smartphone to be completely assembled in its Sri City facility, was out in the Indian market. "It was exceptionally smooth," Jain says. "Really exceptional." According to Xiaomi's Global Vice-President Hugo Barra, quoted in another news report, a similar Xiaomi unit in Brazil took about three times more time to start rolling out products.

As the world's largest smartphone market, China, has become increasingly saturated and competitive (sales of these devices are reported to be stagnating), and India has overtaken the US to become the second largest market in the world, representing an important new battleground for smartphone makers. Several companies have said they want to shift production here. Last year, Huawei was finally allowed to set up a plant in Tamil Nadu's SIPCOT Special Economic Zone, and allowed to invest an additional $170 million in its Bengaluru R&D centre. The company declined Open's interview request. Samsung Electronics, which last year claimed it was investing around $80 million in an existing plant, now plans to open its third plant in India. Micromax Informatics Ltd, which currently sells the most number of phones in India although it makes most of its handsets in China, has also claimed it is looking to manufacture more phones in India. And perhaps the biggest of them all, Foxconn, the world's largest contract manufacturer of smartphones and other electronics (it works for Apple), which has most of its factories in China, last year announced an investment of $5 billion to open 10- 12 plants in western India by 2020, employing as many as one million workers.

For now, Xiaomi, which partners Foxconn, is assembling phones in its India unit. "This is like a chicken-and- egg story. Unless there is any smartphone manufacturing happening in the country, you won't have local component suppliers," Jain says. "But now that we are here. Local sourcing and production will happen eventually." According to Jain, several such component suppliers, most of whom are located in China, have also begun to express an interest in coming to India.

The smartphone market is creating a unique ecosystem, says Jain. Local demand is drawing manufacturing bases here. And over time, as these bases gain in experience and a local component supply chain comes into existence, along with a ready supply of skilled and inexpensive labour, it is not impossible, he says, that phones will be manufactured here to be exported to markets elsewhere.

The 'Make In India' campaign, the promise to convert India into a global manufacturing hub, is possibly the Narendra Modi Government's most ambitious plan. And the 'Make In India Week', the culmination of Modi's various travels and efforts, is proportionately vast in scale. Spread over an area of 220,000 square metres, comprising 27 enormous halls on Mumbai's MMRDA Grounds, the exhibition is a sight to behold. There are government delegations from 49 countries, business delegations from 68 nations, several important Central and state ministers and bureaucrats, and even chief ministers from different states attempting to woo investors. There are industry captains, smaller businessmen who have travelled from across the country, and exhibits that range from monstrous trucks to a small plane created by a hobbyist- pilot, set across the arena. Every session ends in a flurry of pushes and shoves, as smaller businessmen, their visiting cards in hand, push their way forward to network with foreign companies. One session, involving Polish businessmen, has an entire event set aside where they and their Indian counterparts thrash out the possibilities of doing business together. Outside, under large multicoloured images of the campaign's lion logo, golf cars zip this way and that, shepherding businessmen and ministers from one session to another as their security guards run alongside, guns in hand.

The Modi Government's push for setting up the country as a manufacturing hub is also crucial. According to estimates, around 10 million workers join the labour force every year. Some, like the economist Arvind Panagariya, vice-chairman of NITI Aayog, see this as an opportunity. "For many countries like Japan, they have lots of capital but lack labour," he says at one of the sessions. "For us, it's the opposite. We have lots of labour but lack capital."

Manufacturing currently contributes around 18 per cent of economic output in India. The Government hopes to raise that to 25 per cent by 2022. By comparison, manufacturing accounts for 31 per cent of China's GDP. The proportion is 33 per cent in Thailand and 22 per cent in Indonesia.

Signs of India's emergence as a mass manufacturing hub are not restricted to the electronics and smartphone industry.

General Motors claimed last year that it will double the size of its plant in Pune, and put in another $1 billion to develop new car models for the Indian market. Cisco, the Silicon Valley-based networking solutions giant that promised to pump in $60 million for training and facility expansion last year, announced a plan to start a new plant in Pune at one of the sessions. Ford has started a sprawling car assembly plant spread across 460 acres in Sanand, close to Ahmedabad in Gujarat.

According to a recent report by the India Electronics and Semiconductor Association (IESA), the Government has received 156 proposals with investment commitments of Rs 1.14 lakh crore over the last 20 months.

At another session at the event, Cisco's CEO John Chambers claims that India has enormous potential to become the manufacturing hub of Asia. "Eighteen months ago, I said, 'If you want to bet on one country, it is India'… If you still haven't invested in India, you may miss the bus." A day later, the router company's India head, Dinesh Malkani, is equally ebullient. "I have never been this excited about India," he says. "Skill is here, the startup ecosystem is here. We have this once-in-a-lifetime opportunity, really." Cisco is currently part of several state-led initiatives in India, including the Digital India and Smart City projects. With the largest development centre outside the US, Cisco's India arm has also been investing and acquiring a series of startups.

Last year, Nidec, one of the world's largest motor manufacturers, established its first manufacturing plant about 122 km away from Delhi in the Japanese Zone of the Rajasthan town of Neemrana. There are currently plans of opening another 12 such townships, according to the Japan External Trade Organisation in India. The Nidec unit, said to be employing around 5,000 people, was established so as to tap what it believes is a huge market for motors abroad. "When I first came to India in 1974, and even later on my second visit in 1997, there was really nothing here. I'd have never believed India would grow so much. You couldn't even get enough skilled workers," Katsuhiko Takano, Nidec India's CEO and managing director, says. "But now the workforce is excellent. With government support in India, I'm pretty confident manufacturing in India will do well."

The Government thrust appears to have already met with some success. Foreign direct investment to India nearly doubled last year to an estimated $59 billion. According to Kant, this is just the beginning, and the Centre's efforts will begin to show more impressive results very soon. India's GDP grew at an officially estimated rate of 7.3 per cent in the three months ending 31 December 2015, and Kant expects it to rise to 7.6 per cent this year and 8-9 per cent in the next few years.

Maintaining the edge, however, won't be easy. Roads, ports, access to power, governmental bureaucracy, will all have to dramatically improve. "We will have to admit that it is often cheaper to move products from China to India than to transport [goods] from Mumbai to Delhi. Access to power is not cheap either," says Vinod Sharma, managing director of Deki Electronics, which builds capacitors, and chairman of the National Committee on Information, Communication Technology & Electronics of the Confederation of Indian Industry (CII), a co-organiser of the show. "But it looks like things will improve."

According to BVR Mohan Reddy, chairman of Nasscom and executive chairman of Cyient Ltd, the trick will be in not just 'assembling in India'. "For true change to come, for 'Make In India' to really take off, it will need to have four elements—innovation, design, manufacture and service. Apart from being manufactured here, products will need to be innovated upon and designed here, and there needs to be good service for those products here."

During one session, Grant Kuo, managing director of the Indian arm of the Taiwanese company MediaTek—one of the world's top chipmakers that has in the last two years upped its investments in India, opening an R&D facility in Bengaluru, apart from an existing plant in Noida, and committed investments of around $200 million to India—is asked what he thinks about the Indian market and whether large companies will deem it attractive enough to set up factories here. To illustrate his response, he resorts to a slideshow about the scope of the cellphone market in India. But, realising perhaps that this doesn't quite express his enthusiasm, he decides to go impromptu. Speaking in English with a heavy Taiwanese inflection, he explains, with raised hands, "It is a big, big market. What we did in China. I think we will do here."