India-EU FTA: A New Era in Semiconductor and Clean-Tech Cooperation

The India–EU Free Trade Agreement (FTA) tests whether strategic alignment can become an industrial reality. Following its conclusion, on January 27, the India-EU FTA happens at a crucial stage in global supply-chain rearrangement. For the first time, the European Union and India have explicitly included semiconductor and clean-technology cooperation within a trade framework. This signals an ambition to build supply-chain alternatives to Chinese dominance. However, the critical question that remains largely unexamined is whether EU-India cooperation can realistically reduce dependence on Chinese capabilities, or whether India faces insurmountable structural constraints.

India's emerging semiconductor ecosystem

India's semiconductor manufacturing capacity remains at an early stage but is accelerating. The India Semiconductor Mission (ISM), approved in December 2021 under a ₹76,000-crore ($9.1 billion) outlay, has cleared ten projects across six states, covering fabrication, assembly and testing. This has turned India into a budding producer, and in October 2025, Kaynes Semicon delivered the first commercial shipment of Made-in-India chips to California’s Alpha & Omega Semiconductor, marking India’s formal entry into export-grade semiconductor assembly and testing (OSAT). While symbolising capability, this milestone masks underlying structural gaps.

India’s semiconductor ecosystem exhibits three important asymmetries. First, design leadership is concentrated in the United States, and India produces engineering talent but no chip architecture. Second, there is an absence of fabrication capacity; the closest commitment is IGSS Ventures’ 300-acre high-tech semiconductor park in Tamil Nadu (targeting operations by 2027-28), yet investment timelines remain fluid. Third, India lacks indigenous capacity in critical inputs such as photolithography masks, extreme ultraviolet lithography systems, and high-purity materials. This indicates that India’s current semiconductor advantage lies essentially in low-cost, labour-intensive assembly and testing—precisely the area where China, Vietnam and Taiwan already dominate.

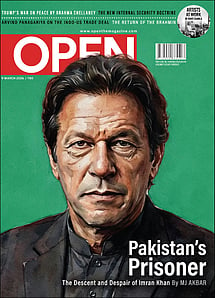

Imran Khan: Pakistan’s Prisoner

27 Feb 2026 - Vol 04 | Issue 60

The descent and despair of Imran Khan

In contrast, China controls approximately 88% of India’s imports of integrated circuits ($5.46 billion in H1 2025 alone), a figure that has risen by 79% since 2017. China’s well-funded integration—from design to fabrication to packaging—offers structural cost and quality advantages that tariff reduction alone cannot overcome. The FTA’s zero-duty tariff on semiconductor machinery will marginally increase Indian OSAT competitiveness, but does not address the core issue of the absence of indigenous fabs and design capabilities.

EU-India semiconductor MOU: ambition meets implementation reality

The first official institutional linkage between the two partners has been the semiconductor commitment under the EU-India Trade and Technology Council. Both sides have pledged to pursue joint research and development in chip design, heterogeneous integration, sustainable semiconductor manufacturing, and talent exchange. In principle, this framework seeks to address India’s design gap through European intellectual property and engineering capabilities.

However, history offers cautionary lessons. The EU’s successful semiconductor partnerships with Taiwan were supported by three conditions: (1) Taiwan’s prior expertise in advanced OSAT and wafer-fabrication services; (2) European willingness to invest €43 billion under the Chips Act with firm investment commitments; and (3) two decades of bilateral trust-building. These preconditions are absent in the India-EU partnership. No EU semiconductor company has committed binding fab investment in India, and the announced partnerships remain research-stage agreements without production commitments.

The quantitative gap highlights the challenge. Indian Semiconductor Mission projects require €2–3 billion in investment per facility, while EU semiconductor projects often involve €30 billion or more per site. The FTA’s zero tariffs on machinery reduce Indian production costs marginally, but this is insufficient to bridge such vast gaps. If the EU intends to replicate its Taiwan playbook, it must match that ambition in India with proportionate, multi-billion-euro anchor investments and long-term purchase commitments.

Clean tech as the key driver of supply-chain realignment

The more reliable alternative to Chinese hegemony lies not in semiconductors but in clean technology. India’s clean-technology market is projected to reach $90–135 billion by 2030 across solar, wind, batteries, green hydrogen and electric vehicles. Moreover, India has an indigenous manufacturing base in solar photovoltaic modules, wind turbines, and lithium-ion battery assembly, segments where China currently supplies 94% of Indian battery imports and maintains dominance.

The EU-India partnership is explicitly focused on this vulnerability. The Netherlands and India have agreed to coordinate green-hydrogen manufacturing, and India is targeting $10 billion in FDI for 10 GW of electrolysers by 2030. This commitment makes a credible case: India offers abundant renewable energy resources, rapid manufacturing growth, and low labour costs. Unlike semiconductors, both partners possess complementary capabilities in this domain.

The credibility paradox

The India-EU supply-chain alternative remains credible in clean technologies, where India has scale advantages and indigenous capabilities, but remains aspirational in semiconductors, where structural gaps persist. The February 2025 semiconductor MOU reflects political intent rather than market capacity. If the EU genuinely seeks to reduce dependence on Chinese semiconductors, it has two real choices: either accelerate India’s semiconductor manufacturing through committed investment and technology transfer, or diversify sourcing across Taiwan, South Korea and Japan.

It is worth noting that the FTA’s real supply-chain value lies not in replacing Chinese semiconductors wholesale, but in leveraging EU-India complementarities in clean-technology manufacturing while gradually building India’s OSAT capacity. This pragmatic approach -- simultaneous diversification rather than complete substitution -- reflects the true state of the India-EU technological partnership. Despite structural capacity gaps, this integration is capable of reshaping global clean-tech value chains in the years to come.