The Coming Storm

THESE ARE ANXIOUS days for Indian markets and the economy. In mid-March, ever since it became clear that the country would not be immune from the spread of the coronavirus outbreak, financial markets have been hammered to multi-year lows. On one occasion, a circuit breaker was triggered and trading had to be halted for some time as the indices plunged by more than 10 per cent. While the stock market indices are not accurate barometers of the overall performance of the economy, they are important indicators of sentiment, a key ingredient of economic activity anywhere.

If markets betray nervousness, there are some positive features to the real economy as well. Some macroeconomic indicators tell the story clearly. One parameter where India falters often, the current account deficit (CAD), has steadily narrowed down to 0.2 per cent of gross domestic product (GDP) in the last quarter (December 2019) from as high as 2 per cent of GDP in the June 2019 quarter. This is a clear indicator that India's external sector is not vulnerable. The recent decline in global crude oil prices to $30 per barrel is another indicator that external vulnerabilities will remain muted. Analysts calculate that even if oil prices average to $45 per barrel in fiscal 2021, the CAD could narrow even further by 0.3 per cent of GDP. This factors in the disruption from migrant remittances from West Asia in the wake of the coronavirus pandemic.

Where India faces trouble is its domestic economy. Here the dynamics are clear. As state after state goes into a quasi-lockdown mode by emphasising social distancing, the trade-off is one between a reduction in the spread of the viral infection and a decrease in both demand and supply. Social distancing will lead to an increase in social benefits but the private costs—in terms of lost wages, incomes, earnings and sales—will rise. The pandemic is best seen as an external shock to the economy that affects both demand and supply almost simultaneously. This will adversely affect all sectors of the economy but the immediate effect of the lockdown will be in the form of a demand crunch.

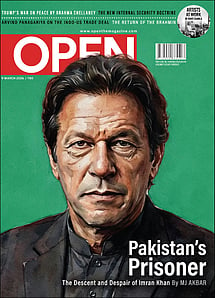

Imran Khan: Pakistan’s Prisoner

27 Feb 2026 - Vol 04 | Issue 60

The descent and despair of Imran Khan

All is not beyond hope, however. There is plenty the Government and the Reserve Bank of India (RBI) can do, especially if they coordinate their policy actions. Analysts had expected that the RBI is likely to go in for policy rate cuts totalling anywhere from 25 to 40 basis points. These cuts could well be taken to a higher level. The key to preventing a disruption lies in ensuring abundant credit flow to the sectors that need liquidity. From this perspective, it is important that policy rate cuts be frontloaded before the economic malaise hits India and not when it finds itself in it. There were expectations of a rate cut when RBI governor Shaktikanta Das called an impromptu press conference on March 16th. In the event, that did not happen.

Where the Government can step up and meet the demand challenge is by transferring a significant amount of money—say, Rs 5,000—to a family or an economic unit. It has channels available to do that. There is the Jan Dhan platform that allows such transfers via electronic means in a relatively corruption-free manner. Then there are PM Kisan beneficiaries who could do with another dose of money. Finally, the reliable MGNREGS is always there to funnel money for this purpose. A stimulus of up to Rs 50,000 crore imparted in this manner is certainly within the fiscal capabilities of the Centre. Imparted in this direct manner, it can go some distance in preventing an outright demand collapse.

AS DEMAND CONTRACTS, transactions take a backseat. With Covid-19 snapping up more than 8,000 lives and infecting 200,000-plus globally, social distancing is the new normal. As germophobia spreads, befuddled administrators down shutters of schools, malls, theatres, swimming pools, gyms—and now, workplaces, as remote working gets real with companies like PayTM, Flipkart, Snapdeal, Uber, Ola, Swiggy, Wipro and Tech Mahindra asking their employees to work from home, while others contemplate a lockdown if the situation worsens.

The intensity of it all can be gauged from what the Asian Development Bank said on March 13th—that the virus can shrink the global domestic production from 0.1 to 0.4 per cent. Goldman Sachs has predicted a 2.5 per cent drop on an annualised basis in the first quarter of this year which, with luck, may recover if the virus stops spreading in late spring. Or else, it's the abyss.

Though the spread of the virus has been slow in India so far, the consequent hit on the financial market was unforgiving. On March 12th, the coronavirus-triggered bloodbath on the bourses resulted in the 30-share index BSE Sensex hitting a 52-week low ending 2,919 points lower, and the slide continues, as if in free fall. That episode on March 12th alone shaved off the wealth of India's top billionaires significantly as, among others, Reliance Industries chairman Mukesh Ambani lost $1.8 billion, Adani Group chairman Gautam Adani lost $1.5 billion, HCL chairman Shiv Nadar lost $1.1 billion. It's not just the Dalal Street that is impacted by the World Health Organization-declared pandemic, but small and medium businesses too, which currently account for 45 per cent of India's total manufacturing output and 40 per cent of exports. Open spoke to a range of businesses to assess the damage.

Mobility is the first and most visible casualty of the outbreak. As people shun travel, industries such as aviation and the tour trade plunge to new depths. With as many as 70 per cent flight cancellations around the world, the airline industry is already in panic mode. In the last month, over 600 international flights have been cancelled and this number is expected to climb with the suspension of tourist visas till April 15th. Even the domestic sector is not spared. "We have seen a 20 per cent reduction in domestic demand," says a senior executive at a low-cost carrier, adding that the airline would be using some of the aircraft it was plying on foreign routes domestically. And though the only saving grace seems to be the softening of crude prices by about 30 per cent, he believes "the Government will pass on the benefit to us after April 1st." Private airport operators too are feeling the pinch and on March 13th wrote to the Government seeking permission to impose 'a nominal passenger facilitation charge' on airfares to cover increased operating expenses.

Lack of mobility has also dented the Indian film industry with the shutting down of over 1,800 cinema halls, terminating all film and television shoots till March 31st and postponing major movie releases. Shoots for Hindi and other regional language films have come to a complete halt.

Approximately, shoots of over 45 TVCs, 55 digital films, 25 feature films, 23 television shows and 14 web shows across India have been impacted by this decision. "These are approximate figures of registered shows and films, but the numbers will only go higher because these days there's a film being shot on every nook and corner of the country," says trade expert Komal Nahata. Even major film productions like Salman Khan's Radhe, Aamir Khan's Laal Singh Chaddha and Ranbir Kapoor's Brahmastra have come to a grinding halt.

The losses are unprecedented considering each of these productions are spending anywhere close to Rs 10-12 lakh per day, and the smaller ones, about Rs 1-2 lakh per shooting day. Films like Baaghi 3 that released during the very week the outbreak was declared a pandemic have suffered the most losses, while others like Angrezi Medium have been scheduled for a re-release. Release dates of much anticipated blockbusters like Rohit Shetty's Sooryavanshi and Kabir Khan's 83 have been postponed.

While single-screen and multiplex owners are estimated to face a minimum of 15-20 per cent cut down in their annual revenue, the Indian film industry will see overall losses of over Rs 400 crore due to the lockdown. However, one silver lining among this is how some prominent filmmakers, including Anurag Kashyap, Anubhav Sinha and Sudhir Mishra, have come together to create a surplus fund for daily wage workers on film sets, like light boys, spot boys, sound assistants, among others.

The health of the tour and travel industry, too, looks bleak. Sabina Chopra, co-founder and COO of Yatra.com, maintains that her company has received close to 35 per cent cancellation queries from overseas travellers. "We have launched a 'Trip Protection Plan' where customers can avail for refund if they want to cancel their travel plans," says Chopra. Rajan Sehgal, co-founder of Plan Your Holiday, believes that travel restrictions will be there for at least three-four months and the business will take a further hit as "China will be off-limit for a full year." Alongside, the hospitality industry too is reeling as Assocham president Niranjan Hiranandani attests of a 20-property hotel chain whose business is already down by 50 per cent.

Reverberations are being felt in the manufacturing and automobile sectors as well amid suspended shipments from China, rising costs and weakening exports. Each year, China accounts for 27 per cent of India's auto component imports. A recent report by Fitch Solutions shows vehicle production in India contract by 8.3 per cent in 2020, largely due to coronavirus. As footfalls to showrooms nosedive by about 30 per cent, supply woes continue for a swathe of manufacturers. Ashim Sharma, partner at Nomura Research Institute, claims that the rollout of BSVI vehicles on April 1st will get delayed as parts will not come in easily to Indian ports from China, adding that electric vehicle (EV) manufacturers are the ones who are actually bearing the brunt of the Chinese lockdown ever since the coronavirus outbreak in Wuhan. Lohia Auto makes both two and three-wheeler EVs and Ayush Lohia, its CEO, is a worried man owing to supply chain disruptions. And now he's concerned about the spread of the virus at home: "Customers are not stepping out and so sales are down 15-20 per cent from the last month, which was already 15 per cent down from the month before," says Lohia.

Arjun Bajaj runs Shinco India, the largest manufacturer and designer of television sets for branded TVs across the country, with an R&D facility in China. Though the China centre is up and running after nearly a month's closure, Bajaj is concerned over shipment issues and rising costs. "If we place the order now, it will take 60 days for it to reach Indian shores because 30 days are taken as lead time and another 30 days [the shipment is] in the sea. Now the problem is that everything needs to be airlifted because the ports are shut and so costs are rising," he elaborates. In the textiles business too, the upheaval is evident. Vishwanath, managing director of the Noida-based Nath Brothers, imports yarn, spare parts and machinery from China and exports finished products to Europe, largely to Italy. Both China and Italy are the most affected by the virus outbreak. As fluctuating supplies fast deplete his inventory, fumigation cost and additional time at ports eat into his profits. The cost of fumigation ranges from Rs 15,000 to Rs 1 lakh depending on the size of the container, he adds. Seconding Vishwanath, and speaking for a wide range of industries, including electronic goods and mobile phones and even furniture and pharma, DK Aggarwal, president of PHD Chamber of Commerce & Industry (PHDCCI) mentions that earlier, exporters used to get payment after they got orders from the US and Europe. "Now some of the orders are not forthcoming and that impacts working capital of these exporters who are faced with a liquidity crunch," he says. So one of the demands of the PHDCCI to the Government is to raise the working capital limit set by banks automatically by 25 per cent across industries at least for the next six months.

In the pharmaceutical sector, about half of pharma products are sourced from China and there are as many as 57 active pharmaceutical ingredients (APIs), antibiotics, vitamins and steroids that may go out of stock if manufacturing plants in China remain under lockdown. Besides, a few days ago, the Directorate General of Foreign Trade came down hard on pharma exporters by restricting 13 APIs, including some paracetamols, vitamins and antibiotics. It's a double whammy for the trade and analysts at India Ratings say that if Covid-19 is not contained in the next three months, the total supply disruptions might be greater than in 2017 when several Chinese companies had halted production in the wake of environmental concerns. In addition to APIs, "there are critical 'Key Starting Materials' which are also supplied by China and while we can tide over 2-3 months, a longer-term disruption will impact production and output integrity," contends Charu Sehgal, partner and leader for life sciences and healthcare, Deloitte India.

In the havoc unleashed by Covid-19 on demand and supply, Trivitron Healthcare, a medical devices company, is faced with a peculiar issue. They were about to start a factory in Xinjiang, China, but are not getting a single executive from India to set foot there. Dr Jameel Khan, Head of R&D at Trivitron Healthcare, says, "Virus evolution is a constant process and every two years, some virus or the other will grip the earth. Coronavirus is just a new strain and we should not get so worked up." On a wing and a prayer, India Inc would surely hope Khan's utterances come true.

(Additional reporting by Divya Unny)