Electronic Cars Pick up Speed on Indian Roads

FOR a person who has spent the last 10 years goading the Government and the automobile industry to look at electricity more seriously as an energy source for Indian vehicles, Sohinder Gill, director, corporate affairs, of the Society of Manufacturers of Electric Vehicles (SMEV), and CEO of Hero Electric, which manufactures electric two-wheelers, has a cautious tone today.

"I think there should be no more [Government] statements now [about the policy on electric vehicles]," Gill says. "The industry has gotten all jittery. Instead, there should be some action, some solid action, until the next statement."

Gill's apprehensions are understandable. India, currently the world's fifth largest automobile market, is preparing itself for what is possibly one of the biggest automobile overhaul plans in history. The Government wants to curtail the sale of all petrol and diesel powered vehicles by 2030, and to ensure that these are replaced with electric ones. The target of 2030 is very ambitious, considering even countries like France and the UK—which have a larger presence of electric vehicles (EV) and a stronger supporting ecosystem—are seeking to ban fossil fuel-based vehicles only by 2040. India's Government has been blunt and aggressive in its talk. Nitin Gadkari, Union Minister of Road, Transport and Highways, sent a shiver of anxiety up the spines of the auto industry when he told a gathering of automobile makers in Delhi recently that the country needs to move towards alternative fuels. "I am going to do this, whether you like it or not," he told them at a convention organised by the Society of Indian Automobile Manufacturers. "And I am not going to ask you, I will bulldoze it."

Gill is unsure how possible or even desirable such an all-out ban of petrol and diesel vehicles by 2030 is. "There are some positives. But there are so many things that are yet to fall into place," Gill says. "The country can be largely electric [by 2030], yes. A large percentage of vehicles can definitely be electric by then. But more things still need to happen at the ground level, a lot more."

The end of the internal combustion engine (ICE) across the world is, as several people are beginning to point out, well in sight. Rapid gains in battery technology and the advancement of EVs favour a future where vehicles will be powered with electricity. But this change in gear from the familiar and powerful growl of an internal combustion engine to the whizzing sound of an electric car is likely to be far from smooth. Especially so in India. The country, expected to be the third-largest automobile market by 2020, sells some 21 million vehicles every year. It has an EV segment that is currently almost negligible, with little or no infrastructure support.

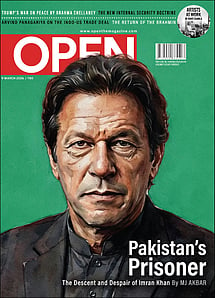

Imran Khan: Pakistan’s Prisoner

27 Feb 2026 - Vol 04 | Issue 60

The descent and despair of Imran Khan

But, according to the Government, this can be achieved and has immense benefits for the country. A joint report released by NITI Aayog earlier this year states that an accelerated adoption of electric and shared vehicles can save up to $60 billion in diesel and petrol costs, and reduce energy demand and carbon emissions by 64 per cent and 37 per cent by 2030, respectively. A new automobile policy that will spell out the rules and include a roadmap for electric vehicles is believed to be in the works and will probably be made public by year-end. Earlier this month, Amitabh Kant, chief executive of the NITI Aayog, while addressing auto industry executives, claimed that because of the country's low per capita ownership of automobiles (an estimated per capita car ownership of 20 vehicles per 1,000 citizens, in comparison to 800 vehicles per 1,000 citizens in the US and 85 per 1,000 citizens in China), India is uniquely positioned to pursue a different model of growth where it will not have to struggle to achieve that target. According to him, electric vehicles will happen in India; the challenge is how to do it rapidly enough and on a sufficiently large scale.

All this aggressive talk and push is forcing automobile companies and auto part manufacturers to draw up early plans for electrification. A few are waiting and watching for a proper policy document to be released and an ecosystem for it to be put in place. But many others have already gotten to work. Suzuki Motor Corp, for instance, in a joint venture with Toshiba Corp and Denso Corp, is setting up a Rs 1,151-crore plant in Gujarat that will start making lithium ion batteries for India and international markets from 2020. Tata Motors is expected to launch an electric version of its Tiago soon, and is apparently also testing such a version of the Nano. Cummins India, an auto engine maker, has announced it is investing in electric vehicle research. Ashok Leyland has partnered with a start-up, SUN Mobility, to develop battery-swapping technology. Ola has introduced a fleet of electricity powered vehicles in Nagpur. All the big car makers, from Audi to Hyundai, have been hinting that their R&D wings are working on electric cars for the Indian market. Very few months pass without talk of a new e-scooter, e-rickshaw or e-bus hitting Indian roads. Internationally, too, there is a lot happening. Battery prices are falling, Volvo has announced that it will not make purely petrol-engine cars after 2019, and even Tesla, that maker of flamboyantly expensive electric automobiles, has begun to turn out models priced within the budget of middle-class motorists in the West.

"We understand this is going to be a big challenge [for the Indian market]… but it is something [at this moment] that is very exciting. We are taking it very seriously," says Bruno Grippay, Nissan Motor India's vice-president of program management, product planning, market intelligence, and EV business & design. Nissan India is currently conducting pilot tests, Grippay reveals, to check the market feasibility of its Nissan Leaf in the country. The Leaf is considered to be the world's highest-selling electric car of all time. Its latest version—available for sale in Japan from next month and in Canada and the US from January next year—can be fully charged in just 40 minutes with fast chargers, and a single charge can cover up to 235 km on European roads. It has hot-wired features like the e-pedal, which allows for single-pedal driving in normal traffic conditions, and a Pro-Pilot semi-autonomous driving feature that can keep the car centred in a motorway lane, stop it from hitting objects that get in the way, and guide the vehicle to park itself if asked to.

Earlier this month, a top Nissan executive told journalists in Japan that the company is also considering the launch of its Note e-Power in India. This has been the second highest-selling vehicle in Japan in the first half of this year, and is being lauded by motor mavens as a revolutionary vehicle. Something in between a pure electric car and the traditional hybrid, it runs on an electric motor but without a plug-in facility. Instead, it has a 1.2-litre, 3-cylinder gasoline engine that does not drive the car but instead works as a generator to charge its batteries. This could be an ideal feature, many think, in countries like India where the plug-in charging infrastructure is almost non-existent at the moment.

But according to Grippay, Nissan is for now focused just on its Leaf and is not considering the Note e-Power for the Indian market. "The Leaf is a very advanced [electric] model. For now, we are looking at its suitability [for Indian roads], the reactions of customers here, its attractiveness [to customers here]," he says.

A FEW DECADES ago, when Chetan Maini was a young student at the University of Michigan, he was part of a team that developed a solar car from scratch. They called the vehicle the Sun Runner. Maini and his teammates, as part of an inter-university competition where they stood first, raced the vehicle around 3,000 kilometres from Florida to Michigan. Later that year, the Sun Runner was put through another race, this time the World Solar Challenge Championship which was sponsored by General Motors, and where Maini and his young teammates raced across the Australian continent, coming in third, right behind Honda. This was back in 1990.

Twenty-seven years down the line, Maini is a changed man. But this anecdote from his youth pushes its way in as he tries to explain his passion for non-fossil- fuelled cars. "This sparked my interest in this field," he says, "and has driven my entire career down the electric mobility path." Five years after his university experiences developing a solar car, Maini began travelling the world trying to understand the nascent technology that powered electric vehicles and started working on the idea that would eventually materialise into India's first electric vehicle, the Reva. "In 1999, I moved back to take Reva forward in India, as bringing electric mobility and solar energy together was the dream," he says.

The Reva, for all its promise, did not take off. Maini sold his company to Mahindra & Mahindra in 2010, where he held an advisory position until recently. "Two decades ago, there was a lack of awareness about climate change and push from the Government; hence the EV ecosystem could not take off," he says. But there has been a significant rise in awareness about climate change, he says, coupled with a governmental push for a future of electric vehicles. "At the same time, there is a great momentum in the global EV space which is creating strong ripples in the Indian automotive sector as well."

So many years after he launched the country's first electric vehicle, this new-found ebullience in the EV sector is pushing Maini once again towards another disruptive idea.

One of the biggest issues that plagues electric vehicles is that of its battery. Globally, the cost of lithium ion batteries is decreasing. Prices have already dropped, as Gill points out, from $600-$500 a few years ago to $250 now. "We all believe this will further halve in another few years," he says. At some point in the near future, it is assumed that battery prices will fall so drastically that sales of EVs will outstrip those of conventional vehicles. But for now, batteries are the single-most expensive component of these vehicles, making them a lot more expensive than combustion engine ones. Coupled with that is the issue of a lack of a plug-in charging infrastructure, particularly pronounced in India. The phrase 'range anxiety', the fear that an EV will run out of power before it reaches a charging-point, entered the Oxford English Dictionary back in 2013. But although EVs have advanced, this anxiety has far from diminished.

Maini, having teamed up with Uday Khemka of the Sun Group to launch a new company, Sun Mobility, is working on fixing that problem. His new company is developing smart batteries for a wide spectrum of electric vehicles, from cars and buses to scooters, while also simultaneously developing a network of battery-charging stations that will function like petrol filling stations. What Maini is doing isn't just setting up the infrastructure, he is reimagining the way in which energy is stored and how batteries are conceptualised in EVs.

If Maini's plans succeed, the cost of lithium ion batteries will be freed from the sale price of EVs. An EV driver will simply have to reach the nearest station whenever his battery is running low for a fully-charged replacement. The driver will thus not have to pay for the battery itself, but just for its use (as if on rent). "I believe that to enable mass adoption of electric vehicles, we need to address primarily three challenges—high upfront cost of the vehicle, long-refuelling time and range anxiety. As we know, the most expensive part of an electric vehicle is the battery. We expect that separating the cost of battery packs from the vehicle can make the electric vehicle [without battery] equivalent to its gasoline counterpart. We have created proprietary smart bat- tery solutions and have partnered with multiple OEM [original equipment manu- facturers] to integrate the same into platforms from various electric vehicle categories… These smart batteries are modular, easily swappable, highly se- cure, IOT [internet-of-things]- enabled and can be easily refuelled on a pay-as-you go basis," he says. "Also, we are creating an open-architecture infrastructure built around a network of quick interchange battery stations. These stations will refuel electric vehicles at cost lower than and speed faster than conventional petrol pumps."

According to Maini, several leading automotive OEMs like Ashok Leyland have already come on board as strategic partners, while they are also in advanced discussions with several others in different vehicle categories. "While there is a rise in acceptance of this new approach, OEMs in the bus, three-wheeler and two-wheeler segment have started designing vehicles around it. Car OEMs are expected to accept this approach in the next few months," he says. "This approach of partnership where an infrastructure provider like us develops and manages the battery, presents a win-win opportunity for both. This way the automotive OEMs can reduce the product development cycle, thereby enabling them to quickly bring in electric vehicle solutions to the market, and not be concerned by the charging infrastructure network."

THE MOST RAPID change in India's electric vehicle scenario is likely to be wrought by two-wheelers. "People keep talking about the electric car. But I feel like telling them it's not going to be the electric car, but electric scooters that will lead the way," Gill says. "It's going to be electric two-wheelers, then public transport like buses and three-wheelers, cab fleets like Uber and Ola. Electric four wheelers are probably going to be the last to take off."

There are reasons for this belief. There is an estimated 440,000 electric scooters running in India currently, according to the SMEV, out of which Hero Electric, which claims a market share of about 65 per cent, has around 160,000 of them. In comparison, there are only about 12,000 electric four-wheelers. Last year, SMEV estimates around 1,500 electric cars were sold. This year, the figure is expected to rise to about 3,000.

The electric two-wheeler segment itself went through a lull a few years ago, when several companies even went out of business. There was a lot of pessismism in the market, Gill says, because a majority of e-scooters used lead batteries, which are cheaper than lithium ion ones but have a poorer performance and do not last anywhere as long. Since 2015, companies like Hero Electric have begun to bring in two-wheelers that allow consumers to choose and change between lithium ion and lead batteries.

Apart from these established electric two-wheeler manufacturers, several traditional automobile companies are also beginning to develop e-scooters. According to reports, companies like Mahindra & Mahindra and large scooter producers like Bajaj and TVS are also entering this space. One of the most interesting amongst them is a young startup, Ather Energy, which is developing smart scooters. The electric scooter that it is testing out, the S340, will be positioned as a 'premium product' and won't just be an alternate scooter, the firm says. It will be aimed at tech enthusiasts and early adopters, people who will be excited by its smart and connected features that draw on databases and offer a pre-emptive diagnostic system among other things. The S340, according to reports, will have a touchscreen dashboard that will run on Android and sync your smartphone, a battery that will charge faster than most mobile phones, with a top speed of 75 km per hour. "We still believe we have only scratched the surface of the potential of a smart scooter. Once we are on the road, we will be able to explore and adapt to the possibilities," says Tarun Mehta, one of founders of the company.

The two young co-founders of the company, Mehta and Swapnil Jain, who were classmates studying Engineering Design in IIT-Madras, and later worked at Ashok Leyland and General Motors respectively, came together to form Ather Energy after the duo received a patent on a battery management system for lithium ion battery packs which they had worked upon. They decided to launch the company, they say, when their initial market research showed that consumers were willing to shift to electric vehicles, but the market just did not have any product that met their base expectations.

So far, India's largest two-wheeler manufacturer, Hero MotoCorp, has invested Rs 205 crore in the company. Other marquee investors like Tiger Global Management and Flipkart's founders Sachin Bansal and Binny Bansal have also invested. Mehta and Jain have so far missed the 2016 deadline they announced to make the e-scooter available. It is because, Mehta explains, they are building an entirely new product. "Development typically takes around six to eight years. And that's usually on the back of a fairly stable platform, existing technology and established operations," he says. "We are not just building the best two-wheeler, we are also participating in the growth of a new and nascent industry with completely new technology, new platforms and with a very different vendor and re-fuelling infrastructure. A vision like that needs work on not just a product, but the entire ecosystem."

To work around the lack of charging facilities, every purchase of the S340 will come with a charging pod, which can be setup either at home or workplace. They are also setting up public charging infrastructure in every city where the scooter is launched. According to reports, this will involve charging stations at shopping malls, restaurants, cinemas, offices and business parks. "This will not only let users charge their vehicles at high charging speeds, but will also ensure that everyone has access to charging locations," Mehta says.

According to Mehta, the point at which producing electric two-wheelers will cost the same as petrol bikes is only a few years away. The challenge today, he says, lies in convincing the bigger OEMs in the country to make the switch. "The real challenge is the investments already made on ICE by bigger OEMs and the strong brand recall these OEMs have for ICE in the market today. So, it is more about how the Government will work with these OEMs to make the switch to reduce ICE vehicle production, which is not easy. The Government's intent to make the shift to electric vehicles is extremely high," he says. "They want to get there and they are willing to push the industry quite a bit, much more than what any of us expected."

Maini, whose earlier efforts towards a zero-emission vehicle suffered from a lax and uninterested approach both from the Government and auto sector, believes the current goal of going electric by 2030 is the right approach. "An ambitious goal is what we need right now," he says. "Even if we achieve 50-70 per cent, it would still be a significant shift for the electric mobility ecosystem."